APPLICATIONS

‘MACROTHERM’ TPE insulated flexible welding cable designed for the secondary (high current) connection to automatic or hand-held metal arc welding electrodes. These cables are also suitable for flexible use under rugged conditions, on assembly lines and conveyor systems, in machine tool and automatically operated line & spot welding machines.

These cables can also be used for Earthing/return leads, power feeds to electrolytic plating processes, Bus bar connections, transformers & generators etc.

CONSTRUCTION

Conductor - Manufactured using 99.97% pure electrolytic grade class 6 extra flexible annealed bare copper conductor with more than 100% conductivity, according to Indian & International standards viz. IS:8130, BS:6360, IEC:228 & VDE:0295.

Insulation - Insulated with Specially developed thermoplastic Elastomer (TPR/TPE) & HOFR compound resistant to oil & water, in orange / black colors

FEATURES

Outstanding flexibility & durability

High resistance to cuts, tears & abrasion

Resistant to oil, solvents chemicals

Excellent ozone & weather resistance

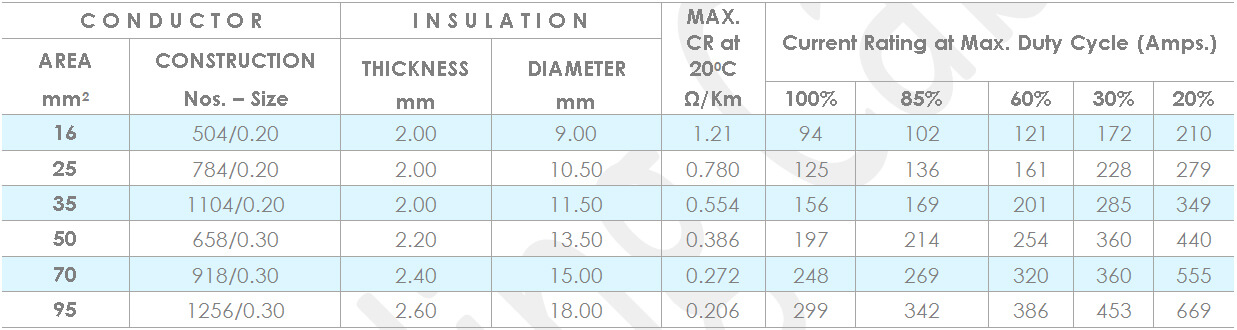

CURRENT RATING

The max. Current Ratings of welding cables for different duly cycles are based on an ambient air temp. of 250 C & max. Conductor temp. of 600 C for general purpose & 900 C for HOFR; NBR-PVC. The percentage duty cycles for various processes & applications are as follows:

Automobile Welding : up to 100%

Semi-automatic Welding : 30% to 85%

Manual Welding : 0% to 60%

Very Intermittent or Occasional Welding : up to 20%

VOLTAGE DROP

When total cable length usage exceeds 15 Mts., it may be necessary to use cables with larger cross sectional area, to ensure the voltage drop is not excessive & welding currents are maintained at adequate levels.

Rating Factors for various ambient temperatures

Standard Supply Lengths:

Coils : 100, 200, 300 Mts.

Wooden Drums : 500 ~ 1000 Mts.